Degree Type: Associate of Applied Science Degree, AAS, Certificate, CER

Pathway: Technical and Professional Studies

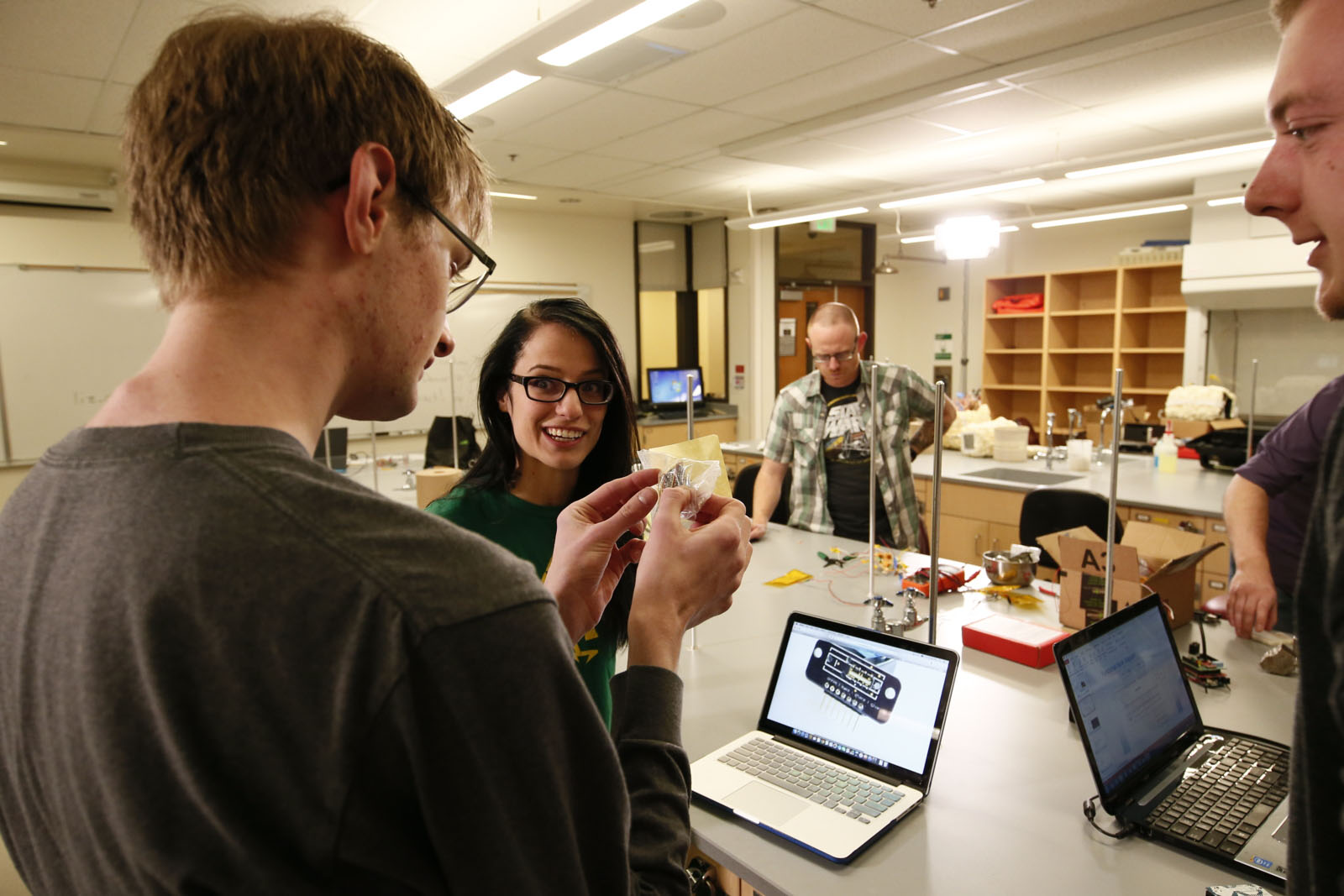

Curious about how technology is driving industries forward? The robotics and automation industry has revolutionized the world, creating a high demand for skilled professionals. With the Robotics and Automation Systems Technology program at Pikes Peak State College, you’ll gain the expertise to build and maintain electronic circuits, operate robotic and automation equipment, and work in automation and control systems. We offer multiple degree and certificate options, giving you the flexibility to prepare for entry-level careers in sectors like communications, manufacturing, and medical.

This degree program in Robotics and Automation is designed to prepare individuals for entry-level technician careers in the robotics and automation field.

This certificate provides students with entry level machining and technology skills.

Students will learn the fundamentals of programmable logic controllers (PLCs) as they are applied in robotics and automation.

Students will acquire skills needed to address operating, monitoring, programming, troubleshooting, and repairing PLC controlled lab trainers as well as actual industrial equipment.

Students will learn about the testing, repair, certifying and troubleshooting of LAN as well as basic skills needed for many careers in electronics and related fields.

Students will learn about electronic assembly methods with an emphasis on processes, safety, component recognition, and soldering techniques for both through hole and surface mount components.

Students will learn to program a robot in a higher-level language to perform various tasks, including the building and interfacing of sensor circuits.

Students will learn the essential components of electronic circuits and related instruments.

Engineers apply the principles of science and mathematics to develop innovative solutions to meet the needs of society. Their work is the link between scientific discoveries and the commercial applications that meet societal and consumer needs. Engineers are in high demand locally, nationally, and around the world. An engineering degree opens the door to many exciting career opportunities.

Explore EngineeringDive into the world of computer science at PPSC and learn coding and computer architecture! Our Associate of Science (AS) program prepares you for high-demand careers in programming, app development, computer systems design, and more. Prepare for a stable, well-paying career in a growing field, with the skills needed for jobs in engineering, math, telecommunications, and more!

Explore Computer Science